We make your technology work

Your partner in high-quality solutions. With 70 years of experience in various sectors, providing assembly solutions.

Scroll down

Wie is Teesing?

Teesing is uw langetermijnpartner voor de ontwikkeling en levering van hoogwaardige assemblages en gerelateerde diensten voor het transport, de controle, de afdichting, de distributie, de filtratie, de zuivering en de meting van gassen en vloeistoffen.

Teesing werkt nauw samen met partners, zowel inhoudelijk als organisatorisch, waardoor zij voortdurend aan de eisen van hun markt kunnen voldoen.

Met meer dan 70 jaar ervaring staat Teesing klaar voor uw uitdaging.

Onze toegevoegde waarde

Naast het leveren van componenten zit onze kracht in het leveren van toegevoegde waarde.

Componenten van een gas- of vloeistof systeem vereisen vaak nauwkeurige montage volgens de richtlijnen van de fabrikant en vereisen speciale tools om te komen tot een gegarandeerd lekvrije verbinding.

Lees verder

Onze sales engineers zijn specialisten in gas- en vloeistofsystemen, met ieder hun eigen specialisatie. Zo komen ze tot producten en combinaties die technische uitdagingen oplossen.

Lees verder

Teesing is voorzien van een eigen cleanroom waar producten gereinigd, gemonteerd, getest en dubbel verpakt kunnen worden volgens de reinheid eisen van onze klanten.

Lees verder

Producten worden verpakt en geëtiketteerd om fouten in levering zoveel mogelijk te beperken en te zorgen voor een optimale service aan klanten. Indien nodig kunnen producten worden verpakt en geëtiketteerd volgens klantspecificaties.

Lees verder

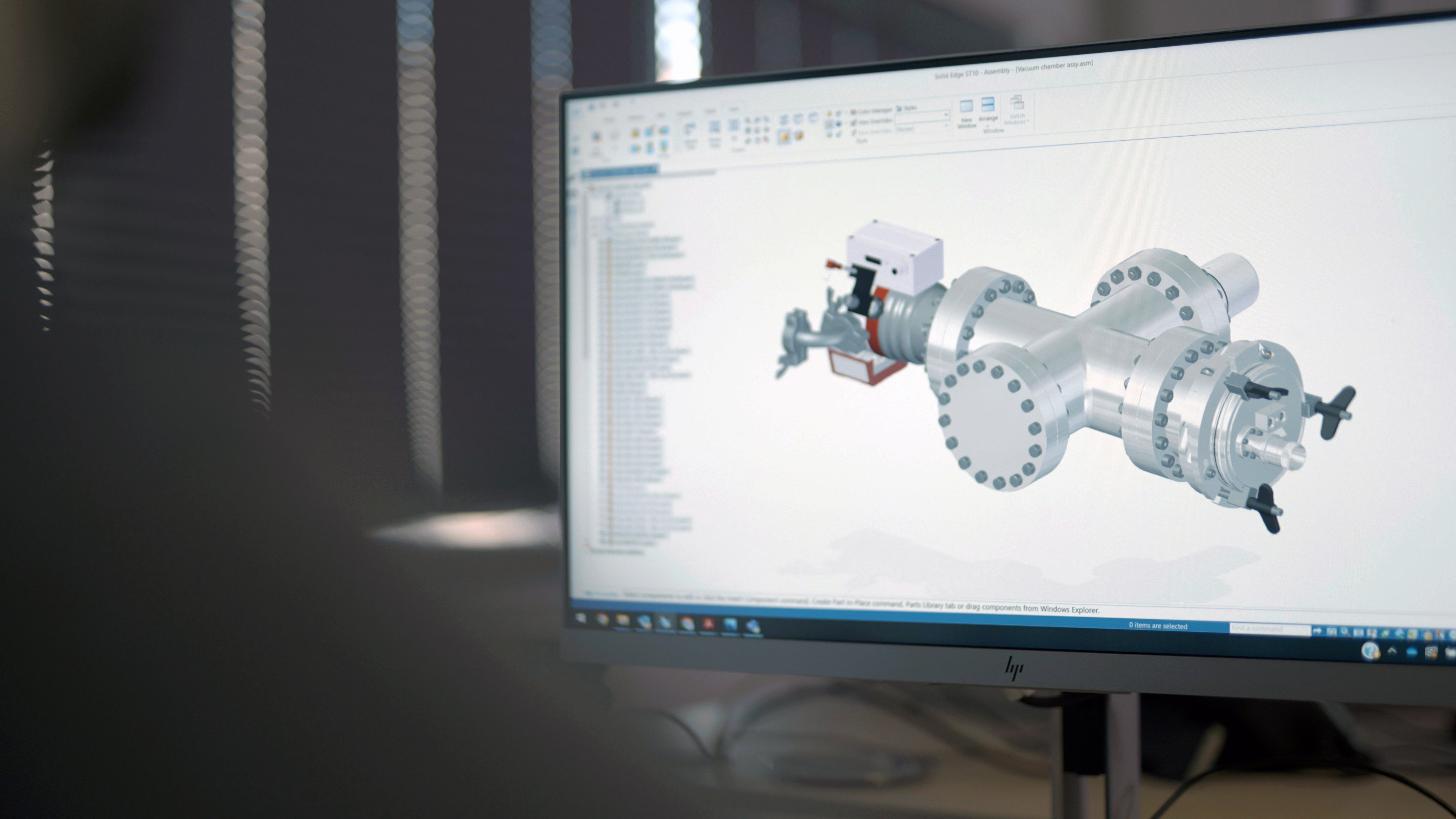

Door nauw samen te werken met onze klanten en met ondersteuning van flow simulatie software, kunnen wij de juiste producten en samenstellingen voor elk specifiek project uitwerken.

Lees verder

Teesing heeft de faciliteiten om producten na assemblage te testen. Naast de technische inspecties kunnen producten getest worden op lekkages met 20 bar lucht of 40 bar gedemineraliseerd water.

Lees verderDeze video is niet zichtbaar vanwege uw cookie voorkeuren.

Nieuws

Nieuwe ontwikkelingen, beurzen en evenementen en meer.

Teesing Group heeft een nieuwe bestuursstructuur. De operationele leiding komt in handen van de Operational Board om de continuïteit te waarborgen en de ambitieuze groei in goede banen te leiden.

Met de feedback van onze klanten en de focus waar Teesing naar toe gaat hebben we de lay-out en indeling van onze website aangepast om zo informatie makkelijker te vinden.

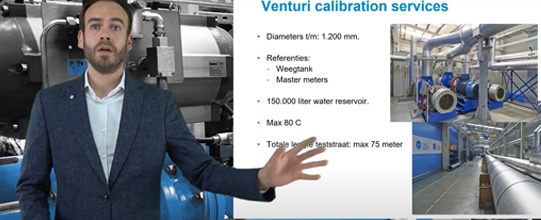

In dit half uur durende webinar laten we u zien wat u nodig hebt om een compleet systeem samen te stellen, de nauwkeurigheid van debietmeting, wanneer en waarom kalibratie nodig is en de verschillen tussen debietcomputers.

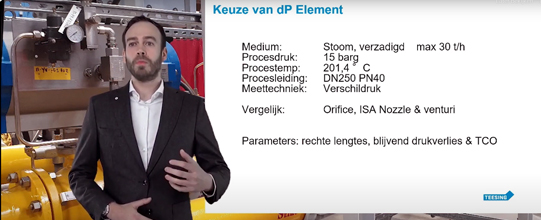

Doe mee aan dit webinar en leer meer over de drukverschilmeter, DP flow elementen, nauwkeurigheden en het selecteren van het juiste element voor uw toepassing!

Teesing worldwide

Teesing is wereldwijd actief in verschillende zeer gespecialiseerde markten,

zoals de medische- en farmaceutische industrie, automobielindustrie, halfgeleiderindustrie en alternatieve brandstoffen.

+(1) 973 383 0691

[email protected]

More information

+31 70 413 07 00

[email protected]

meer informatie

+86 (10) 56865822/56865835

[email protected]

More information

+886-(0)3-5600560

[email protected]

More information

WE MAKE YOUR TECHNOLOGY WORK

NL - Tel. +31 70 413 07 50

USA - Tel. +(1) 973 383 0691

CN - Tel. +86 (10) 56865822/56865835

TW - Tel. +886-(0)3-5600560